conveyor belt thickness measurement|conveyor belt thickness chart : ODM These two benefits help to extend the safe working life of the conveyor belt. Cover thickness measurements can be obtained from steel cord, fabric and solid woven belts. The thickness of both the carry and pulley covers are measured . web28 de dez. de 2022 · Por onde é que você será se eu vou te encontrar. 1y. Mirian Gabriela · February 19, 2022 ·

{plog:ftitle_list}

Resultado da 22 de out. de 2023 · Vídeo amador nacional com essa Brida Nunes transando algemada de quatro em um vídeo amador caseiro. Essa ruiva novinha gostosa ficou entrando na piroca com força e ficou cheia de tesão. Essa safada amadora deu a buceta no pelo e vídeo amador dessa putaria .

The center-to-center distance formula. This conveyor belt measurement formula is one of the most reliable methods for determining the correct length .

These two benefits help to extend the safe working life of the conveyor belt. Cover thickness measurements can be obtained from steel cord, fabric and solid woven belts. The thickness of both the carry and pulley covers are measured .3.In addition, it depends on the use environment of the conveyor belt. The thickness of the top cover of the heat-resistant, cold-resistant, oil-resistant, and acid-resistant conveyor belt should not be less than 4.5mm, and the . Thickness Measurement Techniques: Step-by-step instructions on how to measure the thickness of a 3 ply conveyor belt accurately. Troubleshooting Common Issues: Advice on resolving common issues related .

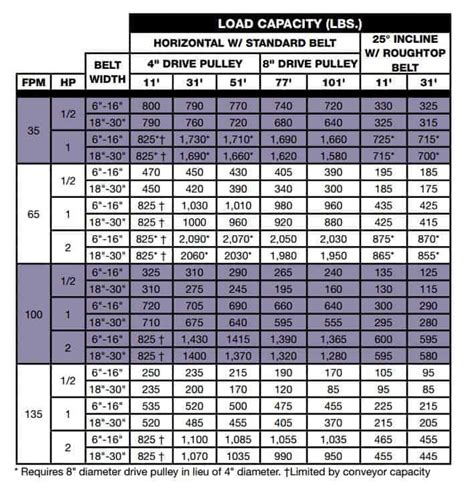

In many industrial applications the conveyor belts thickness monitoring became important. The transport of materials wears out the conveyor belt, that according to the use frequency and material type lead it to reach critical thicknesses and latter its rupture. This work has as main contribution the development of a measurement system of the conveyor belt thickness, .Sonowall 70 Thickness Gauge. The Sonowall 70 is a thickness gauge ideal for conveyor belt thickness measurements. There are several features especially useful for conveyor belt testing. These include a visible gate, bright display and the ability to adjust the frequency if needed. To measure conveyor belt thickness, use a precise thickness gauge or caliper. Place the gauge or caliper against the edge of the conveyor belt where it’s free of any wear or deformations. Ensure the tool is perpendicular to the surface for an accurate measurement. Record the measurement at various points along the belt to get an average . The 5 ply conveyor belt thickness is crucial for heavy-duty applications in various industries. These belts consist of five layers of synthetic fabric, providing enhanced strength, durability, and flexibility. The thickness of a 5 ply conveyor belt typically ranges from 10 mm to 20 mm, making it suitable for handling significant loads and abrasive materials.

Accurate measurement of 4 ply conveyor belt thickness is vital for several reasons: Load Capacity: The thickness of the belt determines its load-bearing capacity. Thicker belts can handle heavier loads without stretching or deforming, making them suitable for demanding applications like mining and bulk material handling. Understanding how to measure a conveyor belt accurately is crucial for ensuring the efficiency and longevity of the conveyor system. A conveyor belt length calculator is an essential tool that simplifies this process by providing precise measurements. . Belt Thickness: The thickness of the conveyor belt, which can affect the length .The troughability of a conveyor belt can be estimated by using this equation, where . m"G = belt mass in kg/m². B = belt width in m. Sz = carcass thickness in mm. Cq = transverse rigidity factor (polyamide = 18, steel cord = 42) Test

However, ultrasonic testing of conveyor belts is limited. The measurement of the total belt thickness is not always possible, especially in case of some steel-reinforced belts combined with fabrics with no sufficient separation between the steel cords. . Belt thickness, composition and measuring accuracy will determine the probe selection .We recently upgraded our Belt Thickness Testing (BTT) units with the addition of a second DMS Go+ thickness measurement device for our Field Service Teams! The suppliers of the unit also undertook .The parallelism of the two probes (Fig. 3) is determined with the use of two laser sensors positioned on both ends of the measuring bars. Devices for measuring conveyor belt thickness and for evaluating the changes in belt transverse and longitudinal profile are already a known technology worldwide (e.g. used by the belt service firm CBM [9]). The article presents the concept of the first in Poland mobile device for measuring the thickness of conveyor belts in motion, implemented as part of the NCBR project (No. 0227 / L-10/2018 [LIDER .

Steel cord conveyor belts — Part 1: Design, dimensions and mechanical requirements for conveyor belts for . ISO 7622-2, Steel cord conveyor belts — Longitudinal traction test — Part 2: Measurement of tensile strength ISO 7623, . 1 Belt thickness mm s 2 Cover thickness carrying side mm s

The measurement of conveyor belt rubber thickness is a critical aspect of conveyor belt management. Utilizing a conveyor belt thickness gauge for regular inspections ensures that the belt remains in optimal .When reviewing thickness measurement methods, factors to consider include target material, type of measurement and more. Your Product Inquiry List; CONTACT US: 503-210-5733; Home; Products. Short Range Sensors. AR100 . Section snippets Materials and methods. Built and developed at the Wrocław University of Science and Technology, a device for continuous measurement of the thickness of conveyor belts in motion (LIDER X no. 0227/L-10/2018) uses the differential method in the measurement process.

conveyor belt width chart

estimating the belt mass and idler dimensions. In most cases, however, they are negligible and can be ignored. Step 2. Select Belt Pitch Use Graphs 2a, 2b, 2c or 2d to select the nominal belt pitch paccording toTe. The graphs also provide an estimate of the required belt width. (For H pitch belts wider than 6"(152.4mm) and T10 pitch belts To verify the correct operation of the measuring system, the thickness of the conveyor belt provided with the LTT was measured by measuring the moving object within the designated operating range of the sensors (20-150 mm). The belt is an object 400 mm wide and 17 400 mm long.

The parallelism of the two probes (Fig. 3) is determined with the use of two laser sensors positioned on both ends of the measuring bars. Devices for measuring conveyor belt thickness and for evaluating the changes in belt transverse and longitudinal profile are already a known technology worldwide (e.g. used by the belt service firm CBM [9]).

Measuring the thickness of a conveyor belt is an important step in determining the overall condition of the belt and identifying any areas of wear or damage. Here are the steps to follow: Select a measuring tool: Several tools can be used to measure the thickness of a conveyor belt, including micrometers, thickness gauges, and ultrasonic . Loads acting on the conveyor belt cause it to undergo a continuous process of wear and tear. One of many symptoms indicating such wear and tear is the abrasion of the carrying cover and the pulley cover. Decrements in the belt’s cross-section reduce its puncture resistance, thus increasing the risk of core damage. Early detection of even the slightest .1 Introduction. Conveyor belts are a cost effective method of transporting bulk materials in many industries worldwide. In the mining industry, conveyor belts are critical components of the supply chain, and the ability to estimate belt wear rates is important to ensure that risk of failure and maintenance activities are managed optimally.

Belt conveyor. In a belt conveyor, the transport belt is attached so it wraps around the drive pulley. The drive pulley (head pulley) is connected to the drive motor and receives motive power from this motor, which changes the frictional force generated between the transport belt and the drive pulley into the driving force. Generally, a belt .By stopping the conveyor belt upon detection of a longitudinal rip event, the system limits the damage associated with these events and . . measurement: min. 0.4 mm - max 0.05 mm Number of splices . in the belt: max.128 Belt Velocity: .of wear for reinforced rubber belts. This maximiz-es the life of the rubber belt by predicting the end of its lifespan. As such, thickness measurement is a tool for effective maintenance and also allows belt changes to be incorporated into the relevant budget cycle. Why ultrasonic testing is needed Reinforced rubber conveyor belts are made of many

conveyor belt weight chart

compression ratio vs compression test

compression rotation test shoulder

conveyor belt thickness chart

Postado em: 28 de fevereiro de 2024 às 18:50. Na noite de ontem (27), a guarnição do 2º Pelotão, durante ronda na Rua Campo Verde, bairro Teotônio Vilela, avistou um .

conveyor belt thickness measurement|conveyor belt thickness chart